Cold Forging

Forging is a metalworking technique used to produce intricately-shaped parts with high rigidity and strength. Shimano is one of the pioneers of the cold-forging technique in Japan, having applied it in actual production since 1962. Development of this technique has enabled Shimano to produce precision parts for bicycles and fishing tackle in large

quantities.

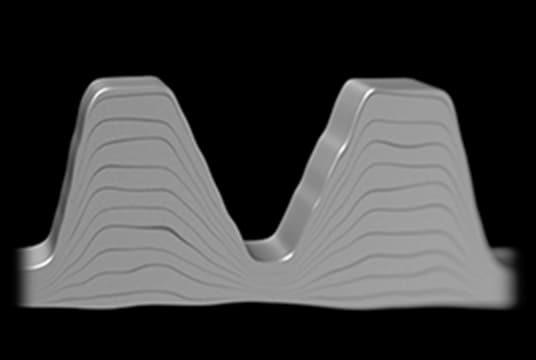

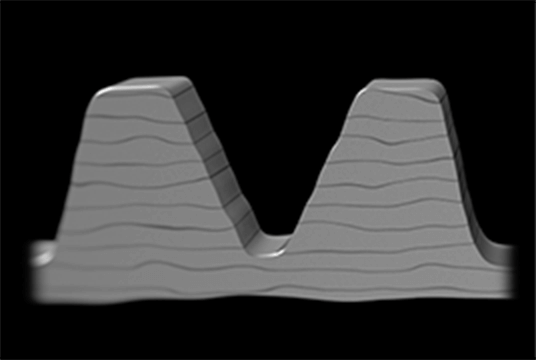

Forging shapes metal using compressive force, transforming the original material into a final, or very close to final, shape.

Forging techniques achieve high rigidity while reducing overall weight. This makes forging ideal for producing strong and lightweight bicycle parts and fishing tackle.

Advantages of Forging